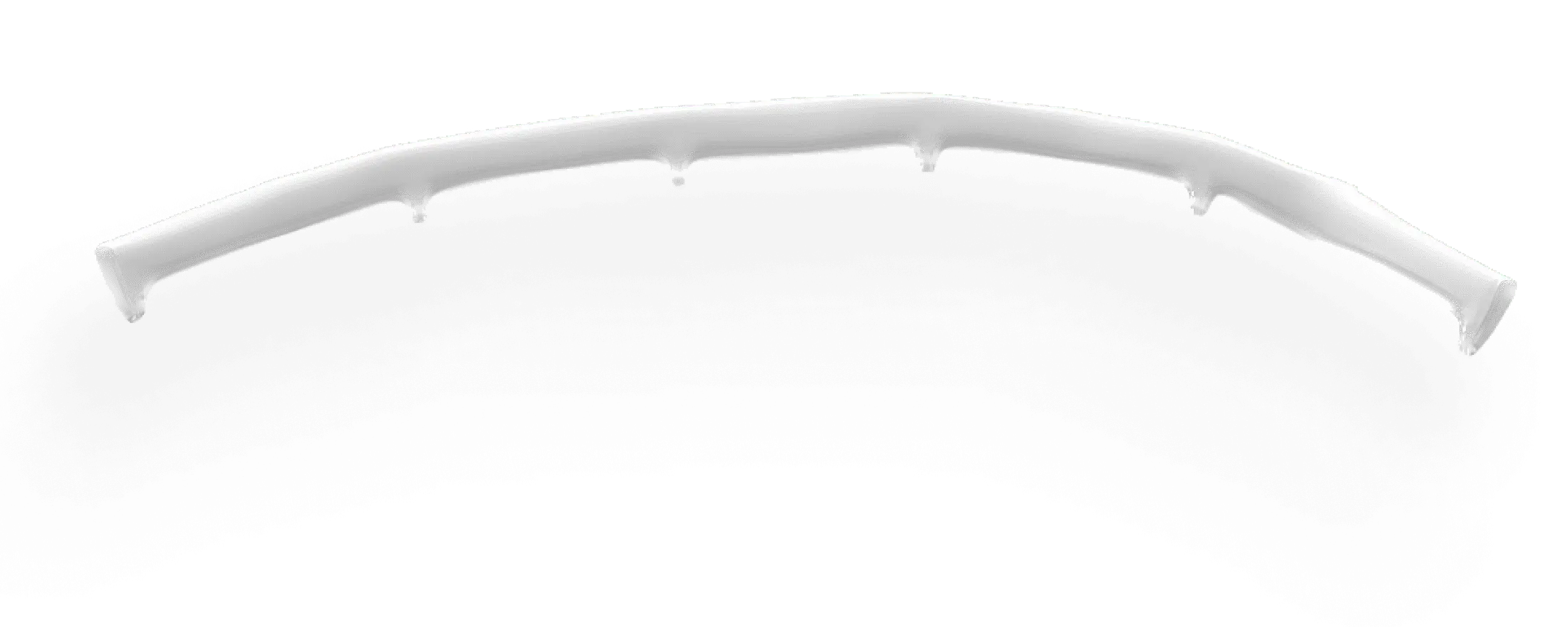

100% digital retainer made of PEEK

The most aesthetic, durable, and comfortable orthodontic retainer, designed for a lasting smile.

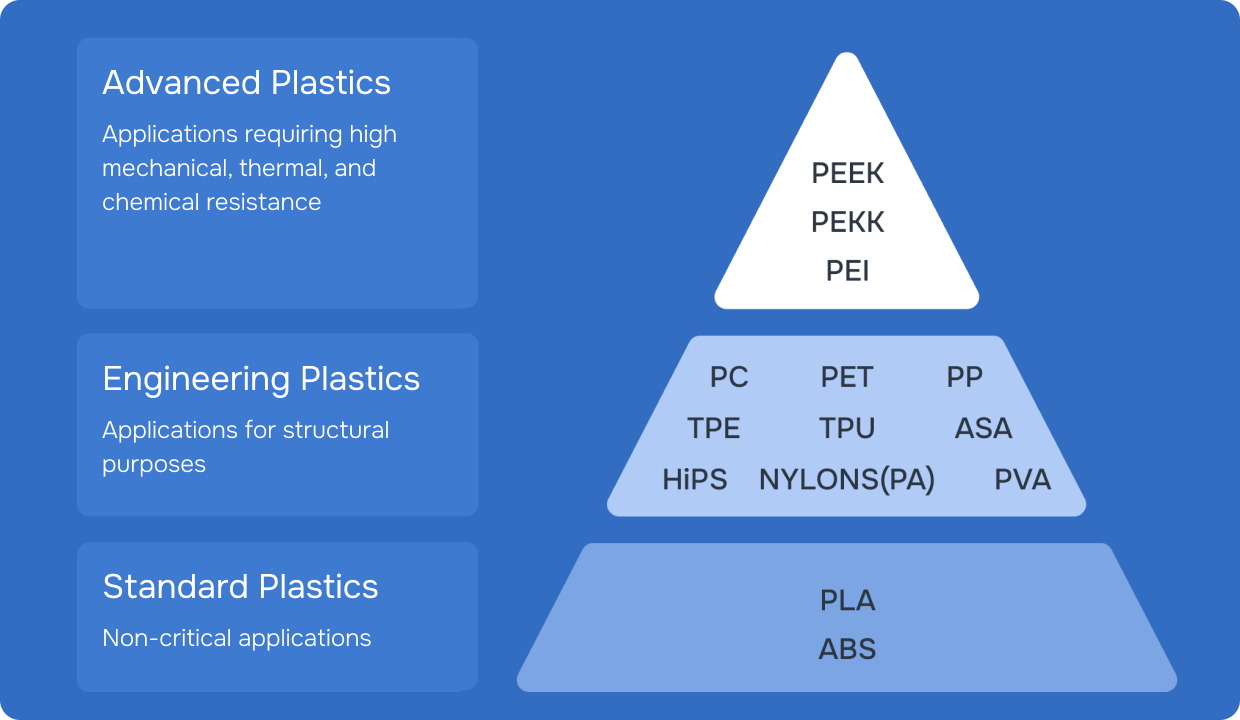

PEEK (Polyetheretherketone)

PEEK belongs to the category of high-performance polymers, positioned at the top of the thermoplastics pyramid. It offers exceptional mechanical and thermal properties, unmatched by standard engineering materials.

This premium-grade polymer is primarily used in high-value applications within demanding sectors such as aerospace, energy, and medicine.

In the medical field, PEEK is notably used to replace intervertebral discs or as a framework for dental prostheses, thanks to its remarkable strength and flexibility.

- Does not deform with chewing

- Does not break

- Slight flexibility

- Biocompatible

- Aesthetic

- Does not discolor

- Does not attract dental plaque

- Metal-free

- Precision milling down to the micron

| Material | Young’s modulus |

| PEEK | 4 Gpa |

| 3-strand stainless steel, 0.215 | 151 Gpa |

| Nitinol | 75 Gpa |

Where chewing can cause plastic deformation in our metal retainers, PEEK will always remain within elastic deformation. It even performs better than NiTi.

Excellent fatigue resistance compared to steel and NiTiNOL

- Excellent mechanical resistance to fracture and torsion

- Outstanding wear resistance

- Flexible material

- Milled from a single block

- Milled in all three spatial dimensions

- Resistant to aging-related degradation

- Maintains its original color over time

- Biocompatible material

- Chemically inert (resistant to acidic food exposure)

- Hypoallergenic

- Metal-free (no Nickel)

- Can be sterilized

- Natural aesthetics with A2 or White shade

- Reduced dental plaque: perfectly polished surface with no undercuts

- Preserves physiological tooth movements thanks to the material’s flexibility

- No artifacts in radiographic examinations

- No electrolytic conductivity

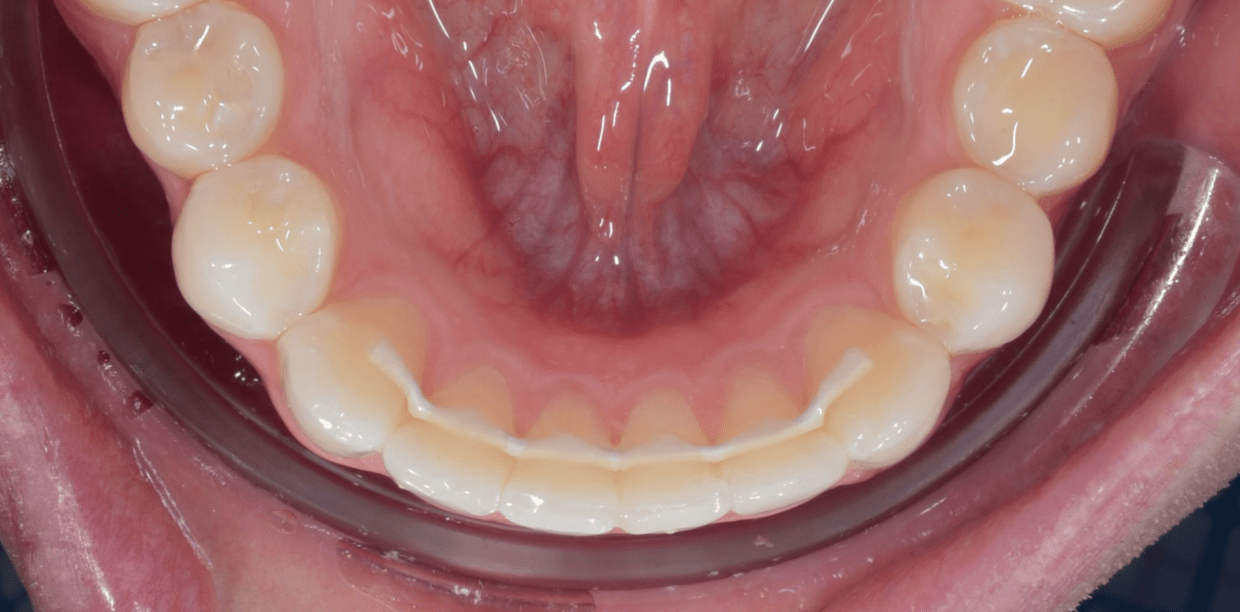

- Natural feel in the mouth

- Flexible material : more comfortable than rigid alternatives

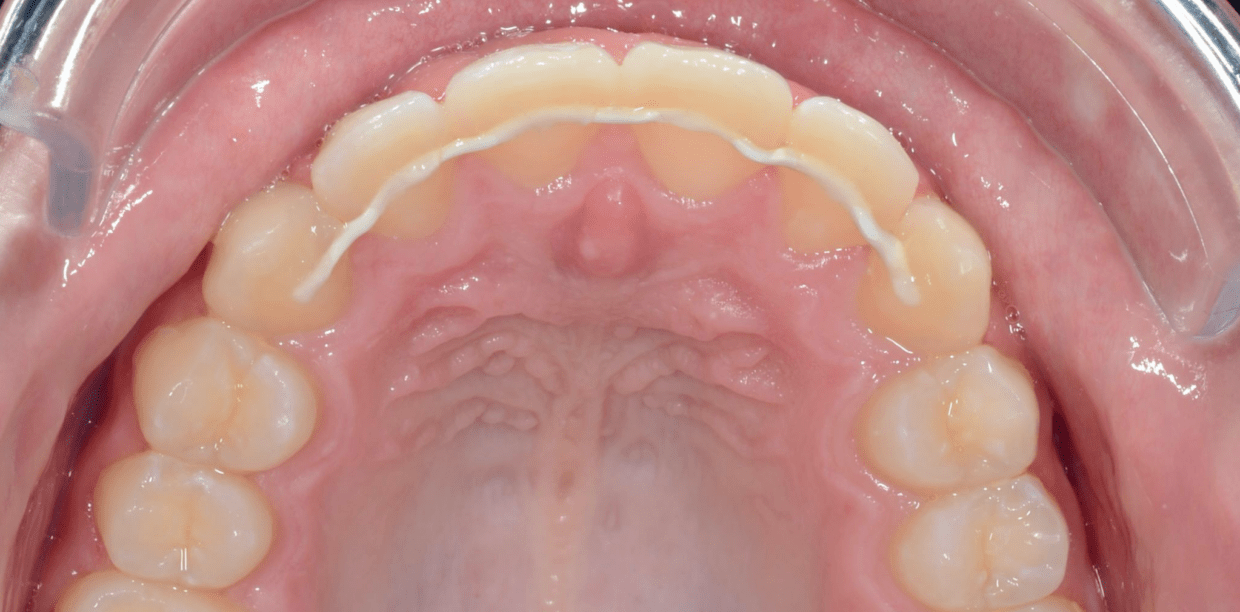

- Polished, smooth surface with gentle geometry

- Perfect 3D fit

- No occlusal interference

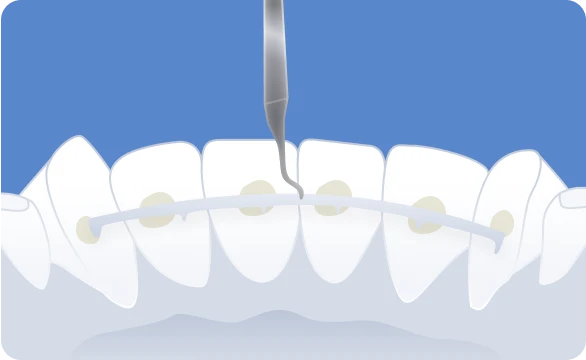

- Easy to place and position

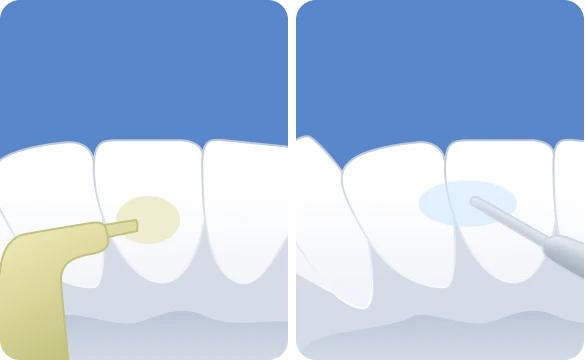

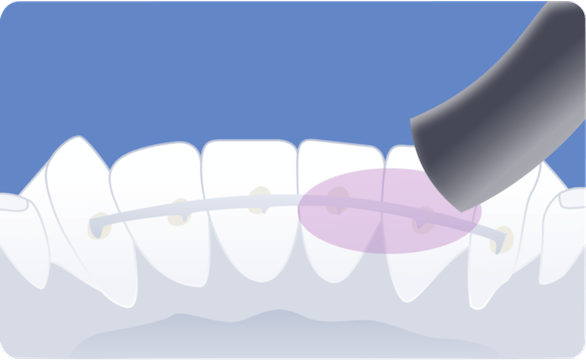

- Very quick bonding

- No discomfort from wires that can irritate the tongue

Bonding protocols

Intellectual Property

- Patent filed on August 22, 2017, in France

- Granted and in effect since March 1, 2019

- REF : FR3070256A1

- Supported by HEGE Conseil

Regulations

- Complies with the requirements of EU Regulation 2017/745

- Manufactured under controlled conditions

- Device monitoring – Materiovigilance in place

- CE-certified raw materials

- Instructions for use available

- Declaration of each device to the ANSM (French National Agency for Medicines and Health Products Safety)

Development was carried out in partnership with INSA

- 9 times stronger than a 0.016″ x 0.016″ steel retainer

- 8 times stronger than a 3-strand 0.0215″ retainer

- 6 times stronger than a Penta-One retainer